Parcel Sorter Built with Flexible Linear Cross-Belt Technology.

In the ever-changing worldwide market requirements for fast, deployable automation solutions for parcels and eCommerce, we designed the TrueSort Advanced to be scaleable, flexible, and modular.

An automated conveyor and sortation system that meets the needs of any parcel sorting application.

TrueSort Advanced is built on the solid foundation that began with previous BlueCrest TrueSort applications. Available in standard configurations, the TrueSort Advanced is designed around flexible linear cross-belt technology. This provides one of the widest material spectrums including items that weigh up to 20kg and down to as little as 50g.

Scaleable

Widest material spectrum available in the industry.

Flexible

Linear cross-belt technology and standard design options provide flexibility to the client.

Tailored

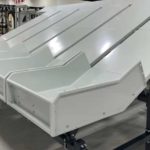

Tailor your system for sorting into bags, carts, or sliding chutes.

Customizable Options

The TrueSort Advanced provides options including sorting into bags, carts, and sliding chutes; or a combination of all three.

OCR Address Reading

Supports reading multiple barcodes and utilizes BlueCrest Sabre OCR in applications requiring address reading.

Product Specifications:

TILT

Design throughput: 6-12k trays per hour

Induction: Manual placement on trays

Barcode/OCR/Image capture options: Inline on the transport, top-facing

Weight & dimension capture: Offline encoding desks

Product mix: Sorts full product mix including irregular small items

Maximum dimensions (LxWxD): 13 in. x 13 in. x 10 in. (US), 330mm x 330mm x 250mm

Minimum dimensions (LxWxD): None

Product weight:

2, 3 or 4 Tiers

0.22 – 10lbs (US)

1 tier

0.1 – 12kg (UK)

Layout options: Linear or loop configuration

Sort to: Sacks, carts, gaylords

PUSH

Design throughput: 5-10k trays per hour

Induction: Manual placement on trays

Barcode/OCR/Image capture options: Inline on the transport, top-facing

Weight & dimension capture: Offline encoding desks

Product mix: Sorts full product mix including irregular small items. Gentle transfer of fragile items.

Maximum dimensions (LxWxD): 40 in. x 28 in. x 20 in. (US), 1000mm x 700mm x 500mm

Minimum dimensions (LxWxD): None

Product weight:

0.22 – 53lbs (dual tray) | 0.22 – 26lbs (single tray) (US)

0.1 – 24kg (dual tray) | 0.1 – 12kg (single tray) (UK)

Layout options: Loop configuration

Sort to: Sacks, carts, gaylords

BOMB BAY

Design throughput: 6-14k trays per hour

Induction: Manual placement on trays

Barcode/OCR/Image capture options: Inline on the transport, top-facing

Weight & dimension capture: Offline encoding desks

Product mix: Sorts full product mix including irregular small items. Exit drop limits used for fragile items

Maximum dimensions (LxWxD): 43 in. x 25 in. x 12 in. (US), 1100mm x 650mm x 300mm

Minimum dimensions (LxWxD): 4 in. x 4 in. x 0.5 in. (US), 102mm x 102mm x 7mm (UK)

Product weight:

0.22 – 22lbs (US)

0.1 – 10kg (UK)

Layout options: Loop configuration

Sort to: Sacks, carts, gaylords

SHOE

Design throughput: 2-5k trays per hour

Induction: Automated induction lanes

Barcode/OCR/Image capture options: Inline on the transport, up to 5 sides

Weight & dimension capture: Inline on the transport

Product mix: Sorts large and heavy packages. Not ideal for regular and small items

Maximum dimensions (LxWxD): 59 in. x 35 in. x 35 in. (US), 1500mm x 900mm x 900mm

Minimum dimensions (LxWxD): 4 in. x 4 in. x 0.5 in. (US), 102mm x 102mm x 7mm (UK)

Product weight:

0.22 – 110lbs (US)

0.1 – 50kg (UK)

Layout options: Linear configuration

Sort to: Gravity feed, controlled descent