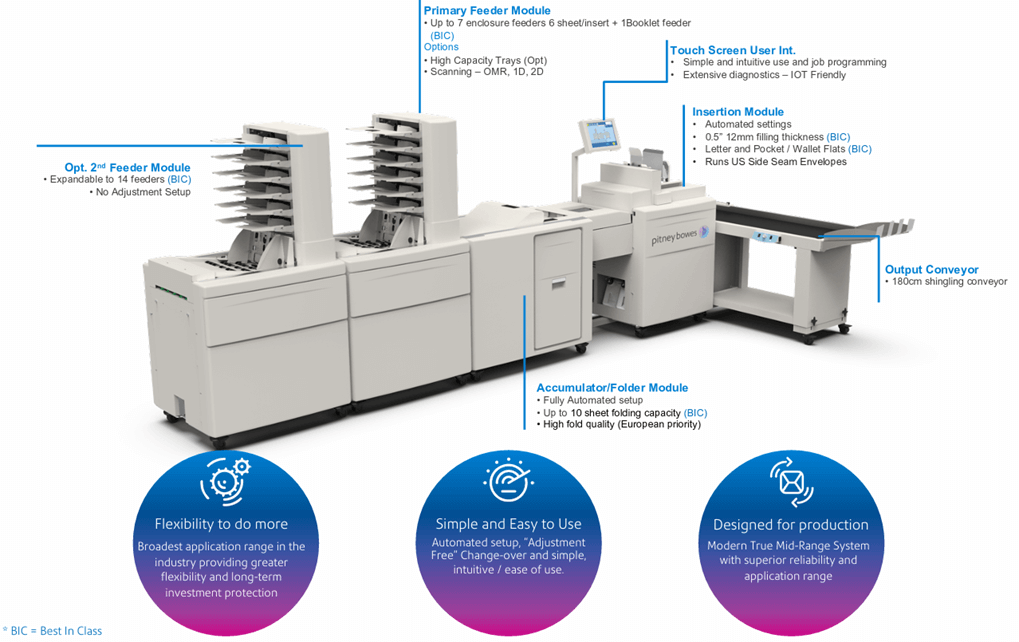

OVERVIEW:

FEATURES:

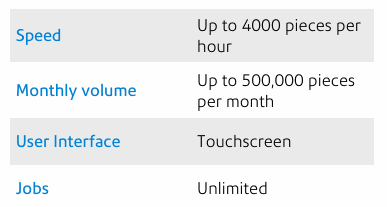

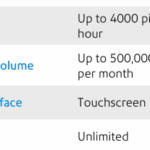

User Interface

Simple and Intuitive

- User interface makes job programming and operation fast and simple

- Automated Set-up – Over 30 adjustments stored with job.

- Envelope and material sizes

- Fold Type and Dimensions

- Feeder assignments and backup feeders

- Sub-setting and feed sequences

- Sealing mode and water level

- Comprehensive help menus and diagnostics

- Unlimited Job Storage

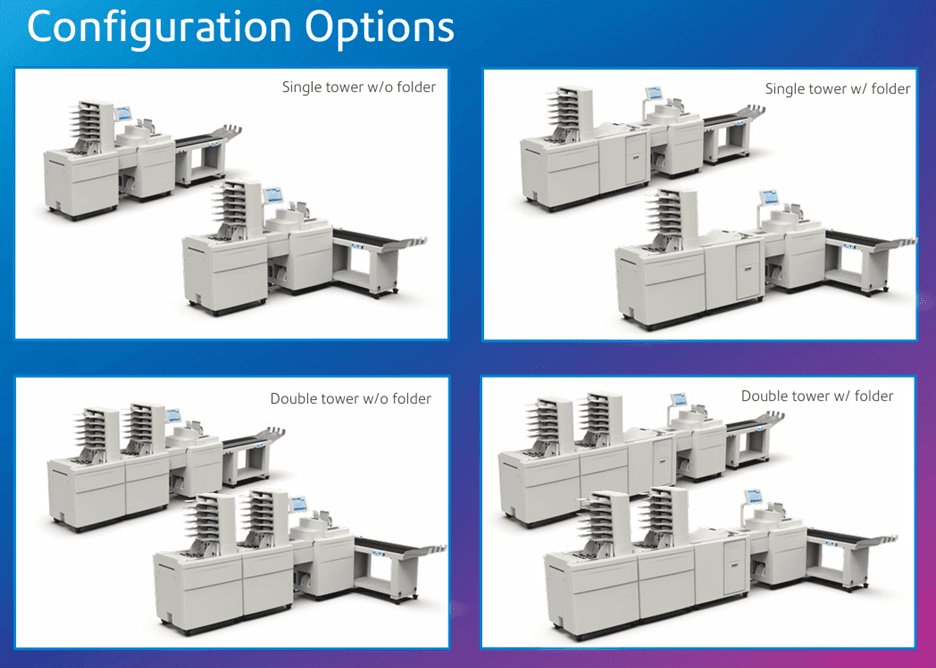

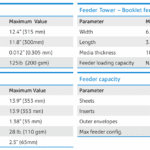

Feeder Tower

Tower Feeders

- Standard 6 feeders per tower

- Top Feed Friction Feed

- Switch from Letter to portrait or landscape flats sizes without adjustments

- Feeds from 60 to 200 gsm with no thickness adjustments

- Fastest insert feeder setup in the industry

- Photocell design reduces effects of paper dust

- Simple operator programming for features:

- Feeder back-up and switching

- Multiple feeds from each bin per mail piece

- Option to Pause or Stop when Bins are empty to reduce stops

Options:

- High capacity bin increases capacity to 700 sheets

- Scanning (OMR, 1D, 2D)

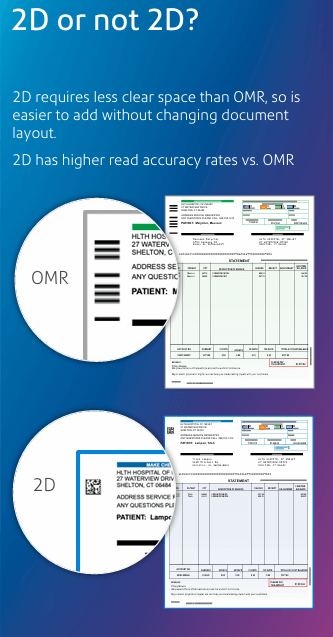

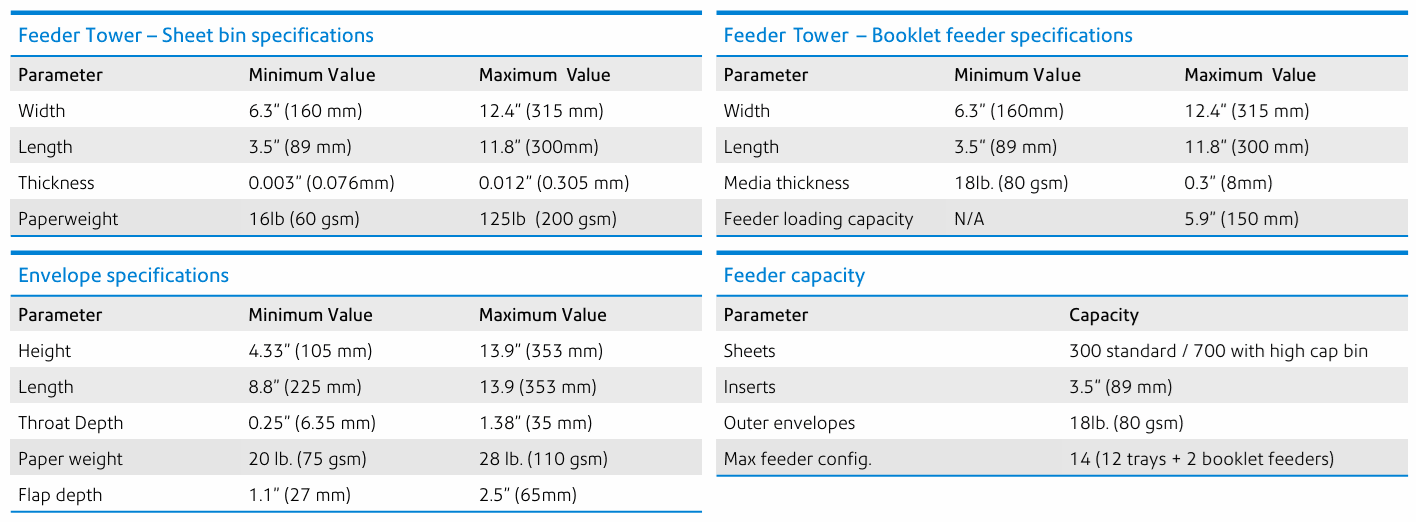

Scanning

- Installed in top bin of tower feeder and support

- Optical Mark Recognition (OMR)

- 1 Dimensional Bar Codes (C128, I2of5, 3of9)

- 2D Bar Code (Data Matrix)

- Two Options available

- OMR and 1D BCR (P/N 10600010)

- 1D and 2D BCR (P/N 10600008)

Booklet Feeder

Standard 1 booklet feeder per tower

- Continuous loading, bottom friction feed technology

- Feeds single sheets to books and booklets up to industry leading 8mm thickness

- Simple thickness and side guide adjustment (same as Envelope Feeder)

Folder module

- Provides Accumulation, Folding and Error Divert

- Provides Accumulation of up to 10 sheets

- Tri-fold up to 8 sheets, half fold up to 10 sheets

- Sub-setting up to 12mm: 12 pages into #10 (tri-fold); 20 pages into 6×9.5; 100 pages in to 10×13

- Automatic Setup

- 3 Buckle Chutes with automated fold settings

- C, Z, Half, and Double Parallel Folds

- Folder Slides out “Folder in a drawer” for easy Material

Access – Similar to Cut Sheet Printer

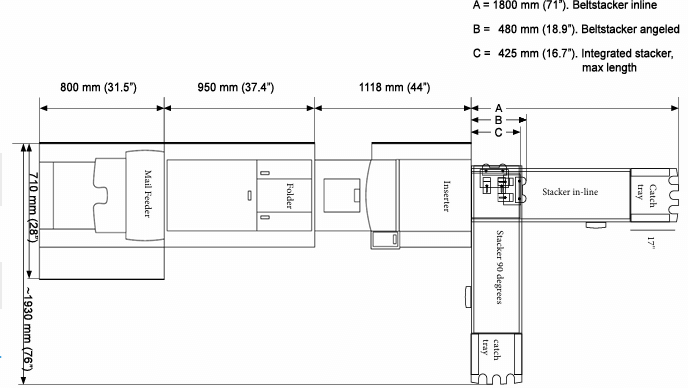

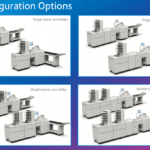

Belt Stacker

The Belt Stacker can be positioned in a 90°angle left or right or straight in line with the rest of the system.

- 180cm shingled stack capacity

- Simple back wall adjustment for different envelopes sizes

- Adjustable speed of shingling

Mail-piece integrity

Smultaneously maximises efficiency and adds a critical layer of security to ensure that the right documents are sent to the right person.

What is mail piece integrity?

Mail piece integrity is what we call the process of making the inserter “intelligent” through the use of barcoding. The inserter’s Scanner or Camera reads the barcode that gives the inserter instructions on what to do with each page. The barcode instructions are things like, “This is page 1 of a 1-page document, so fold and insert it into an envelope,” or “this is page 1 of 3 pages,” so the inserter knows to feed and fold the 3-page document together and insert all 3 pages.

Why does it matter?

Security

Whether every document is a single page or the number of pages vary, mail piece integrity helps organisations avoid the consequences of sending a recipient someone else’s document. Consequences can include litigation, fines, negative brand impact, or a lost customer.

Automation

When documents vary in page-count, barcoding eliminates the need to sort pages. Barcoding tells the inserter automatically how many pages it should feed for any particular recipient’s document.